Life extension and performance improvement

Extending the service life of aging equipment and improving functions

Many problems tend to arise with equipment after use for 30 or 40 years.

- ∙ Aging equipment

- ∙ Unstable processing due to changes in raw water conditions compared to when the equipment was new

- ∙ Higher operating costs

SHI-EV offers investigation and diagnostic services. Based on our results, we propose effective ways to use existing equipment or renovation plans to extend service life and improve functions.

Making use of existing equipment significantly reduces investment compared to equipment replacement.

Our renovation proposal

Present

The facility is 30 to 40 years old.

The water tank has deteriorated considerably and may not be able to survive a major earthquake.

The machines have also degraded; drive units may fail unexpectedly.

The company wants to install energy-saving equipment to cut operating costs.

We undertake discussions to learn about client’s wastewater conditions and equipment operation so that we can offer optimized diagnosis of the existing system..

We also diagnose the condition of the water tanks and other equipment (for example, the drive unit for sedimentation tank) and confirm the earthquake resistance of the water tanks and building (e.g., electrical room, blower room).

Based on the results, we map out a renovation project to prolong the equipment's service life and improve functions to meet the customer’s needs and requirements.

Extending service life

+

improving efficiency

For customers facing problems related to unstable processing due to changes in raw water conditions

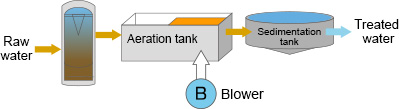

Based on the results of equipment operation diagnosis, we present proposals for stabilizing operation—for example, by installing membrane separation devices.

Extending service life

+

achieving energy savings

For customers who want to reduce the cost of electric power consumed by equipment

We can replace diffuser systems and blowers for aeration tanks with the latest high-efficiency models to achieve significant energy savings.

Extending service life

+

creating energy

For customers who want to recover energy from drain water/waste fluids or who want to reduce equipment operating costs

We offer systems that convert the gas generated during anaerobic treatment of medium- or high-concentration waste fluid into electricity or steam.

cont. Since the system also removes organic substances, it reduces both the number of aeration tanks required and operating costs.

Extending service life

+

Saving space

For customers who want to reduce the space taken by WWT equipment

Significant space can be saved by replacing sedimentation tanks with a configuration that combines an integrated high-speed coagulating sedimentation tank and an existing aeration tank.

Extending service life

+stabilizing operations

+energy savings

+more

We examine various ways to improve functions to meet customer needs and preferences when upgrading equipment to extend service life.

Achievements

Background

The facility was old. Extensive aging deterioration was clearly visible in equipment that had remained in use for around 40 years.

Despite periodic maintenance of the machines, the company was concerned about the deterioration of the concrete water tank and the need for antiearthquake designs.

We examined and planned a renovation project in response to the following customer requests:

- (1)Performing major equipment cost reductions vs. complete renewal

- (2)Allowing construction to proceed without interrupting facility operations

- (3)Reducing operating costs

- (4)Saving space

Proposed renovation

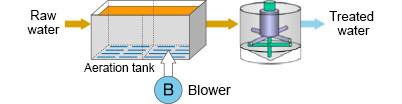

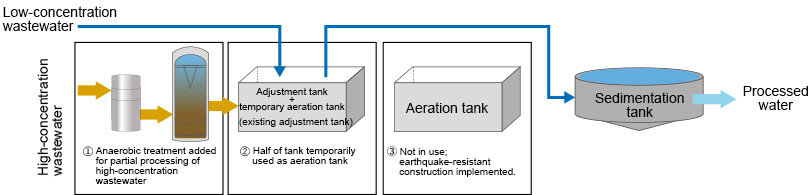

The anaerobic wastewater treatment system pre-processes high-concentration waste fluid to reduce loads on the aeration tank. The anaerobic-treated water and low-concentration wastewater are processed by the aeration tank and sedimentation tank to which life extension measures are applied.

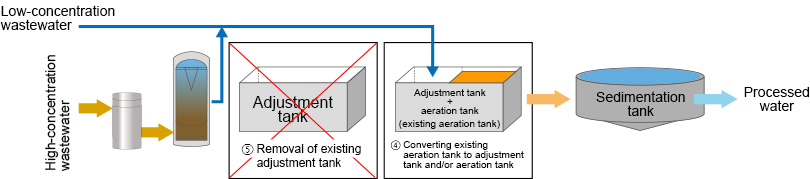

Pre-processing of the high-concentration fluid reduces required aeration tank capacity to about one-third of previous capacity. An empty space created by replacing with a compact aeration tank can be used to accommodate an adjustment tank.

Existing facilityPoor earthquake resistance of the aeration tank; required functional upgrades without interrupting facility operations.

During renovation

After renovation

After renovation (1)

Newly installed anaerobic treatment system processes high-concentration waste fluid.

After renovation (2)

Existing aeration tank is now converted to adjustment tank and aeration tank.

Extending service life

We performed a diagnosis of the aeration tank and sedimentation tank, implemented earthquake-resistant construction, and added a partition to create an adjustment tank and aeration tank. This work will enable use of the equipment for the next several decades.

Optimization

Partial processing of the high-concentration waste fluid stabilizes the quality of the processed water.

Cost saving

We added anaerobic treatment to decrease loads on the aeration tank, significantly reducing power consumption and the amount of generated sludge. Overall operating costs fell by about 70%.

Energy creation

About 10 tons of steam per day is recovered from the high-concentration waste fluid. (Methane gas generated by the anaerobic treatment is used as boiler fuel.)

Space saving

Removing the old adjustment tank reduced the space occupied by the wastewater treatment facility.

Executing construction while the facility continues to operate

After installing the high-concentration waste fluid treatment equipment, we confirmed reduced loads on the aeration tank and converted the adjustment tank into a temporary aeration tank.

Once the temporary aeration tank began operating, we shut down the old aeration tank, performed earthquake-resistant construction, and converted the aeration tank into an adjustment tank and aeration tank.

We completed the renovation project without interrupting facility operations.