Grit chamber systems

Closed system using transfer piping without need for conveyors or skip hoists

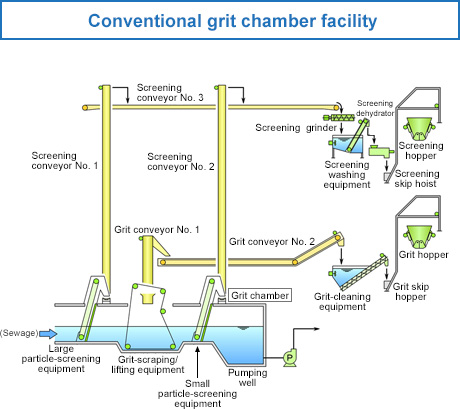

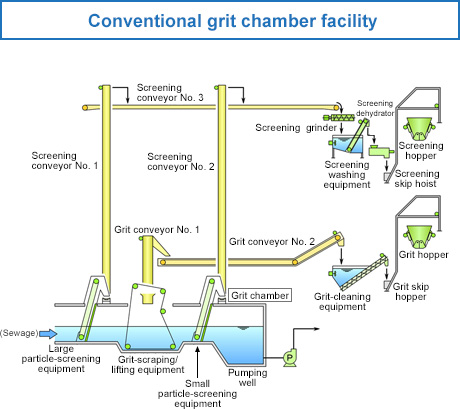

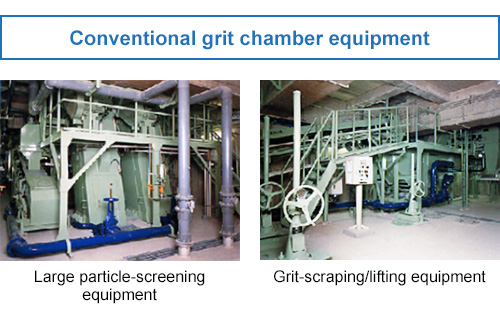

Grit chambers in sewage treatment facilities remove miscellaneous matter and grit carried in by the inflowing sewage, creating foul and malodorous surroundings. Grit chambers are often built deep underground and surrounded by numerous devices whose function is to discharge removed miscellaneous matter to other sites. Thus, they are often fraught with issues pertaining to safety, sanitation, maintenance, and management.

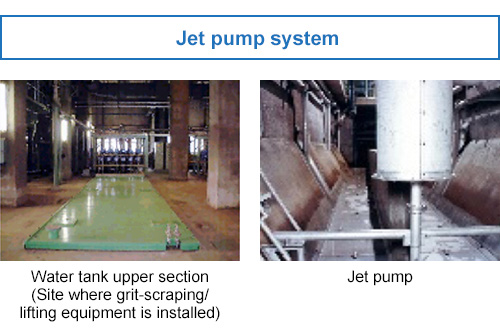

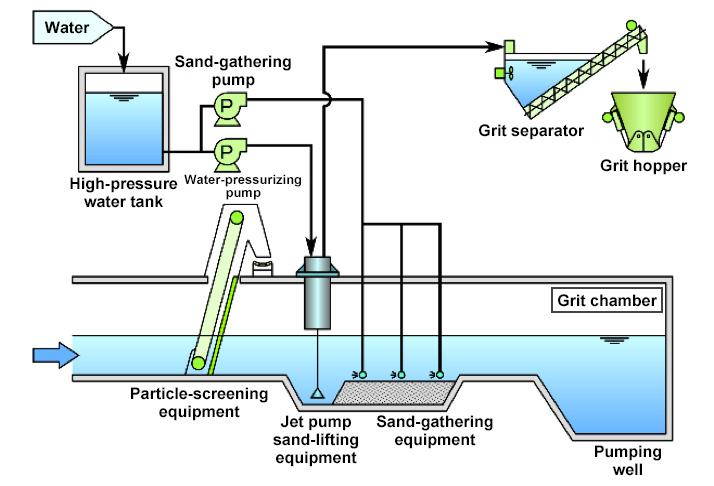

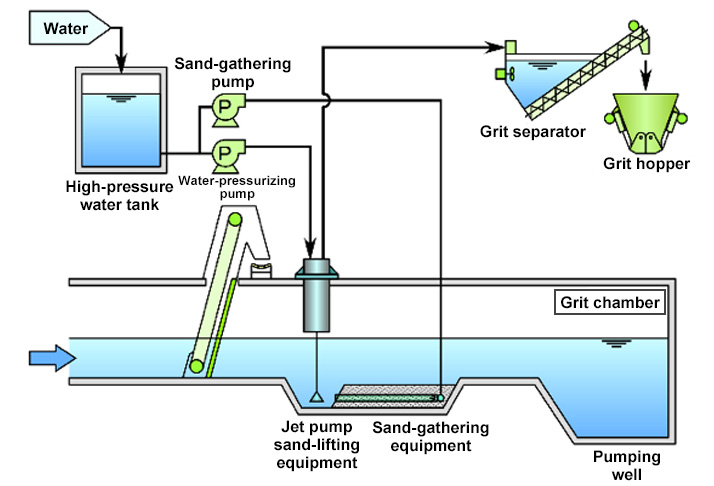

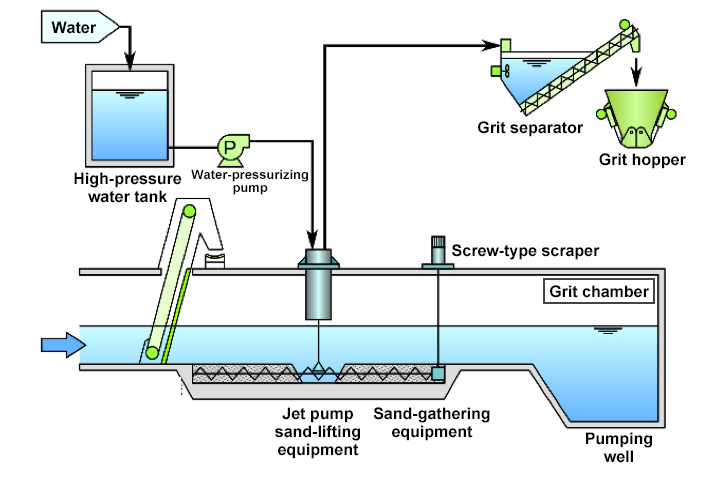

We offer two systems to resolve these issues: residual slurry transport system comprised of a screening crusher and jet pump, and sand-lifting system comprised of sand-gathering equipment and a jet pump.

These systems transport grit and screenings through a pipe to achieve a closed system.

Sumitomo Heavy Industries Environment proposes and delivers numerous systems for grit chamber facilities at sewage treatment plants and pump stations.

Features of SUMITOMO’s Advanced Grit Chamber Systems

-

Closed system using pipe transportation

The system turns screenings/grit into a slurry and transports it through a pipe to achieve simple equipment layout and flow lines.

-

Effective cleaning of screenings/grit

Screenings/grit are transported by high-pressure water from a jet pump. Turbulence inside the pipe effectively cleans residue and grit.

-

Minimal odor generation

Since screenings/grit are transported inside a closed system, there is minimal odor compared to conventional transport methods using conveyors and skip hoists. This can dramatically improve workplaces and the surrounding environment.

-

Allows smaller facilities

Eliminating conveyors (conveyor, skip hoist, etc.) and inspection platforms reduces facility dimensions.

-

Enhanced safety

The system uses fewer moving components, such as conveyors, reducing hazards associated with potential contact with rotating parts during cleaning.

The system improves working environments and simplifies flow lines, ultimately enhancing work safety throughout the facility. -

Lower costs

Switching from conveyors to piping for transport reduces the number of required devices and lowers equipment and maintenance costs.

Examples of applications

- ∙ Sewage treatment plants, pump stations, and facilities where screenings /grit are transported

1. High-/medium-pressure sand-gathering system

2. Ejector-type sand-gathering system

3. Screw-type sand-gathering system