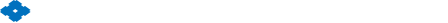

SPIRAL CUTTER crushing/dewatering functioned screen unit with vertical conveyor

Compact integrated screening treatment system capable of capturing, crushing, transporting, dehydrating, and discharging screenings.

The SPIRAL CUTTER is a compact screening treatment system featuring a screen-equipped SUMICUTTER unit, combined with a vertical conveyor that offers screening and dehydration functions. This integrated single-unit system captures, crushes, transports, dehydrates, and discharges screenings.

Minimizing screening volumes to allow screenings to be readily packed in bags/ containers. and transported, the system is ideal for applications with no need for large-scale equipment or subject to maintenance cost constraints.

Features of the SPIRAL CUTTER

-

Minimizes screenings

The integrated organic matter cleaning and dehydration functions significantly reduce the amount of screenings generated without affecting latter-stage processes. They also minimize odor. The resulting screenings can be packed in bags/containers for easy transportation. The system improves working environments and cuts waste disposal costs.

-

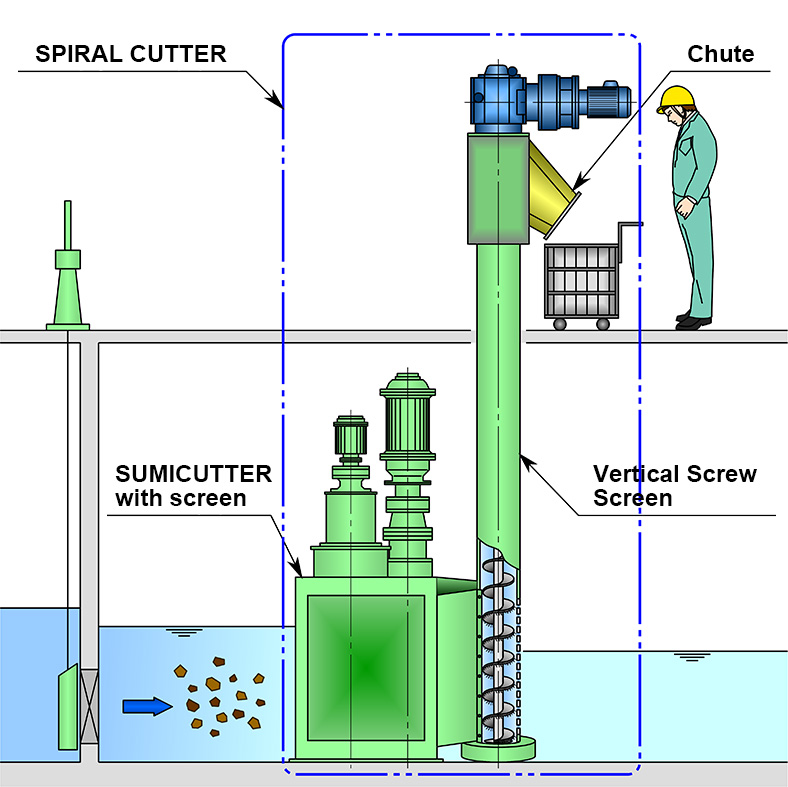

Lifecycle cost reductions

The system has fewer components than conventional systems for compact dimensions and lower lifecycle costs. It’s also easy to maintain.

-

Easy renovation

As a vertical transport unit, when combined with a SUMICUTTER, the conveyor minimizes the space required along the direction of flow. This in turn allows use of the existing opening for renovation construction and the system installation without major modifications of the slab structure.

* The system handles large temporary volumes of sludge, such as flows encountered during cleaning of the inverted siphon and pipe.

Example of applications

Grit chamber/pump station at separated sewer system