Compliance with regulations

Many companies believe too many resources are consumed to comply with the rigorous effluent regulations for the processing of COD, nitrogen, phosphorus, oil, and other substances.

Many companies also believe advanced treatment systems are complex.

For such customers, Sumitomo Heavy Industries Environment proposes systems that are easy to use, save space, ensure stable processed-water quality, and achieve high processing capacity.

- Advanced treatment of nitrogen, phosphorus, and COD

- High-speed thickener for achieving compliance with total volume regulations for COD, even with significant water volumes

- Immersion membrane capable of removing oil

Advanced Treatment of Nitrogen, Phosphorus, and COD

Integration of activated-sludge treatment and coagulating sedimentation treatment (SUMI-SLUDGE system)

In addition to activated-sludge treatment, this system coagulates, adsorbs, and removes decomposing-persistent COD, nitrogen, phosphorus, and other substances by adding flocculant to activated sludge.

Meeting rigorous effluent regulations once required a complex system. Now, the SUMI-SLUDGE system achieves compliance with a single process.

The flocculant also works on activated sludge and maintains high-concentrations of microorganisms suitable for the removal of decomposing-persistent COD.

The system resists fluctuations in water quality and meets strict water-quality standards for confined water areas.

Replacing sedimentation tank with SUMI-THICKER or installing membrane separation tank

By maintaining high sludge concentrations and by circulating flocculant, the equipment achieves efficiency, high resistance to coagulation fluctuations, and high processed-water quality.

High-speed thickener for achieving compliance with total volume regulations for COD, even with high water volumes

With significant volumes of water, treating decomposing-persistent COD with conventional systems entails significant costs, including the cost of membranes and a large sedimentation tank. Even here, we can propose compact, inexpensive systems that incorporate the SUMI-THICKENER system. Space required for installation will decrease by around one-fourth to one-fifth.

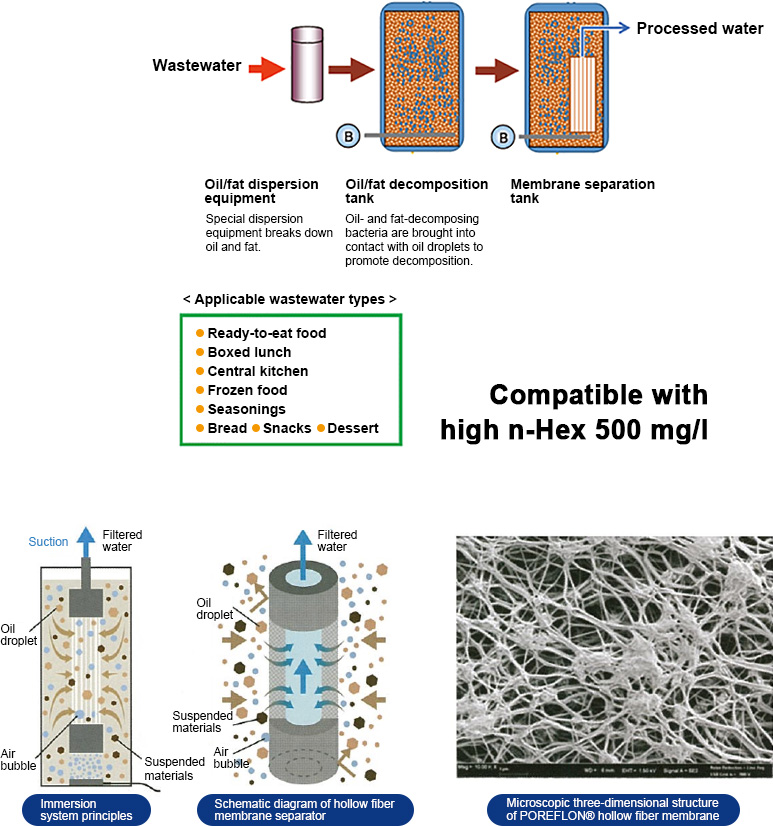

Immersion Membrane Capable of Oil Removal

Even if the raw water contains oil that is difficult to remove, the SUMI-THICKENER system performs biological treatment without using pressure floatation.

Since an immersion membrane is used to separate solids and liquids, the system saves installation space and provides stable processed-water quality.

There’s no need to install a pressure floatation tank, reducing sludge (froth).

- Eliminates concerns about unpleasant odours.

- Biological treatment decomposes oil without pressure floatation.

- Uses highly oil-resistant PTFE membranes.