Aerobic treatment system

Sumitomo Heavy Industries Environment proposes ideal systems based on the specific situation and needs of each customer. We offer an extensive track record of completing projects to increase processing capacity using existing aerobic treatment equipment and projects for upgrading existing equipment. Please contact us for more information.

- Simple, space-saving, high performance

- No risk of sludge outflow

Membrane separation activated-sludge system - Energy-saving aeration system

- Compact size achieved by increased bacteria concentrations

Simple, space-saving, high performance

Replacing coagulating sedimentation + sand filtration with high-speed clarifier

This simple aerobic treatment system features integrated activated-sludge treatment and coagulating sedimentation treatment. The quality of the processed water is equivalent to water processed by coagulating sedimentation treatment systems.

Integration of activated-sludge treatment and coagulating sedimentation tank

Smaller capacity of aeration tank with greater loads

Use of SUMI-THICKENER in the coagulating sedimentation tank

Space-saving configuration

Retention of high concentration of activated sludge (MLSS) in the aeration tank

Stable processed-water quality, even in the face of fluctuations

Application examples: In cases in which compliance with regulatory values for nitrogen, phosphorus, and COD is challenging, or when water volumes are high despite limited installation space

No risk of sludge outflow! Membrane separation activated-sludge system

EV-MAX

- ○Since the system doesn’t require a sedimentation tank, there’s no risk of sludge outflow due to bulking. The immersion membrane ensures thorough separation of solids and liquids throughout the year.

- ○Higher MLSS settings (15,000 mg/l to 20,000 mg/l) allow for use of smaller aeration tanks, enabling significantly smaller equipment footprints than standard activated-sludge equipment.

- ○The high-precision filtration membrane produces high-quality processed water.

- ○The system can be delivered in a short lead time; the capacity of existing facilities can be increased in short construction time frames.

- ○The system helps create simple, compact wastewater treatment facilities and minimizes construction costs.

- ○The system is ideal for recycling wastewater

EVMAX-U

Incorporates a membrane aeration tank. Additional tanks can be added based on production conditions. The unit size is designed to be transportable for dramatic reductions in onsite construction times.

Energy-saving aeration system

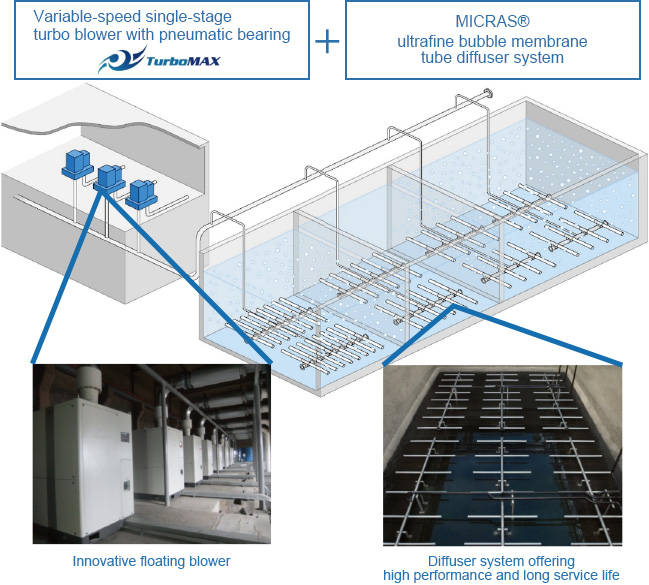

MICRAS + Turbo MAX

The combination of high-efficiency diffuser tubes and energy-saving turbo blowers significantly reduces operating costs.

The TURBO MAX turbo blower conserves energy, requires minimal maintenance, produces low noise, and saves installation space. It features a built-in inverter for automatic control of air flow rates according to DO or water levels and maintains ideal air flow rates without manual intervention.

The combination of high-efficiency diffuser system and blowers achieves remarkable energy-saving performance.

A durable diffuser system and blower with a friction-free pneumatic bearing require minimal maintenance.

Offers broad air flow rate control range and intermittent operation for flexibility in matching inflow loads.

Compact size achieved by increased bacteria concentration

BIO-COMPASS (fluidized carrier)

This aerobic treatment system doesn’t require a sedimentation tank, maintains high sludge concentrations, and is resistant to load fluctuations.

Compact system for pretreating activated sludge and reducing loads on aeration tank

50% reductions in load on aeration tank

Capable of processing wastewater ranging from small to large

Application examples: To expand the processing capacity of existing equipment and to pretreat wastewater

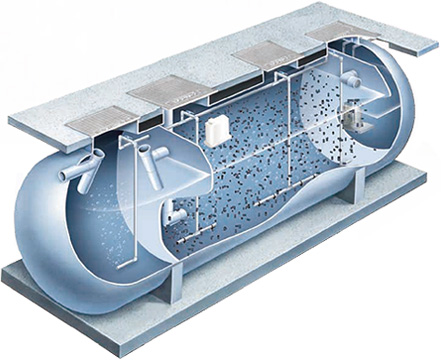

BIO-COMPASS FD

The tank is unitized and horizontally elongated, allowing rapid product delivery at low cost. Capable of processing small to medium volumes of wastewater ranging from 5 mm3/day to 200 mm3/day.

The unit features a high load capacity of up to 6 kg BOD/mm3/day and makes it easy to configure a compact system. It’s also resistant to performance fluctuations. A biofilm forms on the fluid carrier to produce activated sludge.

Compatible with water volumes of 5 m3/day to 200 m3/day

- Raw water: BOD 2,000 mg/L

- Processed water: BOD 20 mg/L to 160 mg/L