Super high-loading coagulation system

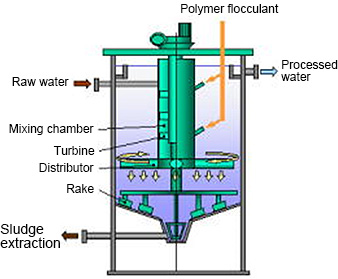

The coagulating sedimentation process is among the most commonly used water treatment processes in which a flocculant or similar material is added to inflowing water to agglutinate fine particles (SS) into flocs. Solids and liquids are then separated to produce clean processed water.

The following illustration shows a typical facility set-up. Due to growing space restrictions in recent years, demand is growing for space-saving equipment. This product meets just this need.

SUMI-THICKENER

Distribution-type super high-loading coagulation equipment

SUMI-THICKENER is a compact, high-speed thickener one-half to one-third the size of a conventional coagulating sedimentation tank. We achieved these dimensions by using a distributor to disperse inflowing water and create uniform ascending currents.

Features of SUMI-THICKENER

Space-saving unit as small as one-half to one-third of the size of conventional coagulating sedimentation systems

The distributor disperses inflowing water to prevent irregular flows. This system can perform treatment using high surface loading.

Integration of coagulation tank and coagulating sedimentation tank

The mixing chamber inside the tank is used to promote reactions with high-molecular flocculant, eliminating the need for a coagulation tank. The system can be installed in confined spaces.

Coagulated flocs with excellent settling performance

The system minimizes fine flocs and forms uniform coagulated flocs by adding a high-molecular flocculant at appropriate intervals.

No damage to coagulated flocs

Coagulated flocs formed in mixing chamber are supplied to the tank without damage caused by water current shearing forces.

Delivery to more than 250 customers site

- Secondary treatment of initially precipitated activated sludge, tertiary treatment, and tertiary treatment for catalytic oxidation

- For clarification of coarse brine and clarification of causticized green liquor

- For treatment of plating wastewater and treatment of wastewater containing heavy metals

- For primary treatment of industrial water

- Wastewater coagulating sedimentation (food wastewater, DIP wastewater, papermaking wastewater)

- For treatment of hydrofluoric acid, treatment of etching wastewater, recovery of magnesium hydroxide, silver recovery

Excellent Pollution Prevention Equipment Award (The Japan Society of Industrial Machinery Manufacturers), Sasaki Award (Japan Technical Association of the Pulp and Paper Industry)

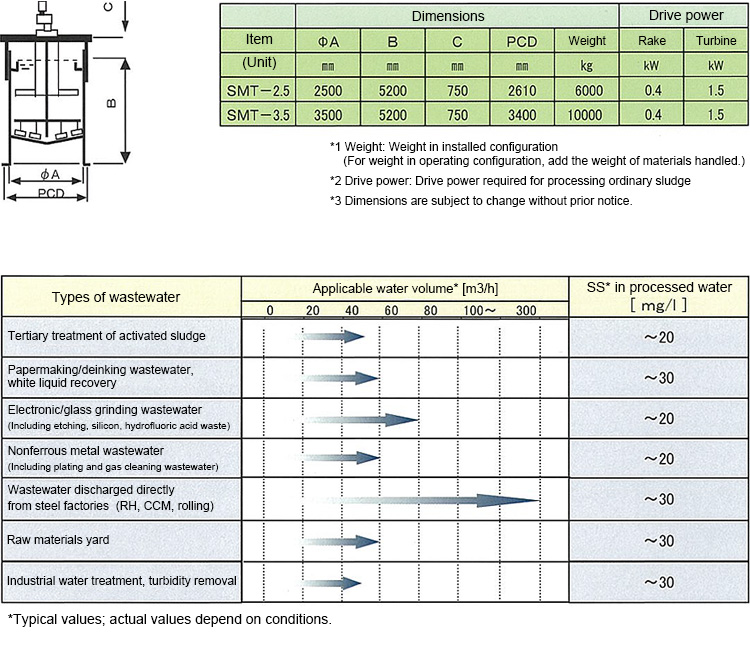

Compact module dimensions

SUMI-THICKENER Zone Separator Model

Floc filtration-type high-speed clarifier

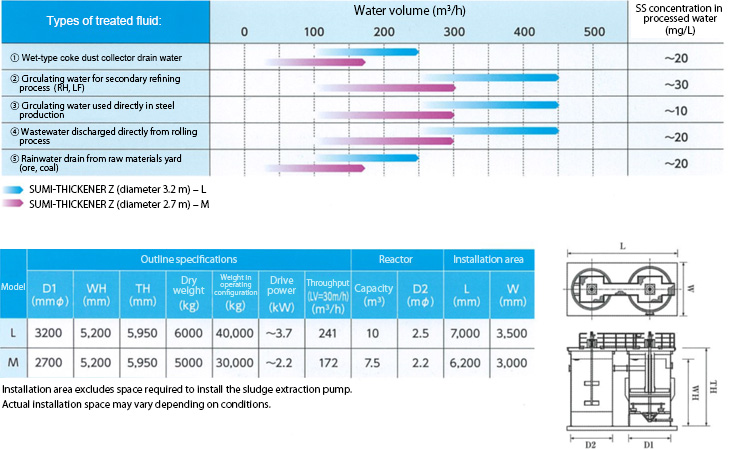

The SUMI-THICKENER Z high-speed clarifier is just one-fifth to one-tenth the size of a conventional coagulating sedimentation tank because it forms a floc layer (sludge blanket) inside the tank. The system combines high-speed treatment and floc filtration to provide clean processed water.

Schematic diagram of equipment

External view

Features of SUMI-THICKENER Z

Equivalent performance with far smaller footprint as compared to conventional sand filter.

SUMI-THICKENER Z forms a floc layer (sludge blanket) that filters and captures minute particles and enlarges flocs. It provides clean processed water using high surface loading.

Examples of SUMI-THICKENER Z application

Significant space savings can be achieved by replacing existing coagulating sedimentation and sand filtration equipment with a single set of coagulating sedimentation equipment.

The flowing motion of the sludge blanket promotes the coagulation of existing flocs and particles in the inflowing water. This means no coagulation tank is required.

Compact module dimensions