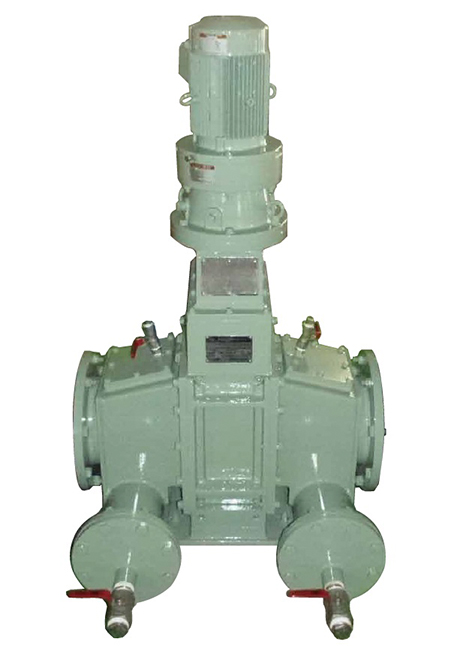

External view

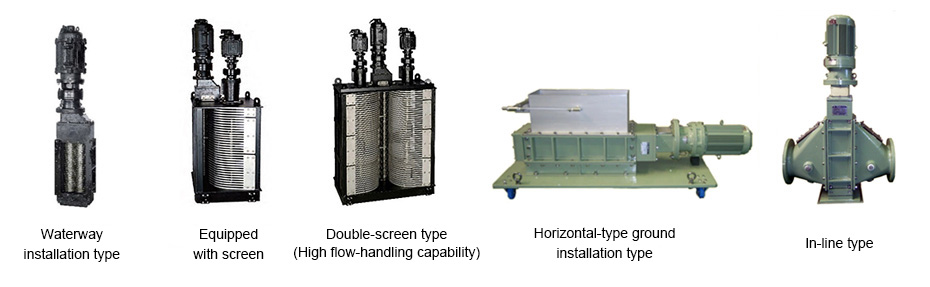

The SUMICUTTER effectively crushes and grinds cloth, wood chips, empty cans, and other materials, rendering them into fragments that will not damage/clog equipment at sewage treatment facilities. The product also significantly reduces associated workload and expenses. Attesting to its performance and durability around the country, the SUMICUTTER is currently deployed in sewage treatment plants, relay pump stations, and factory wastewater treatment facilities across Japan.

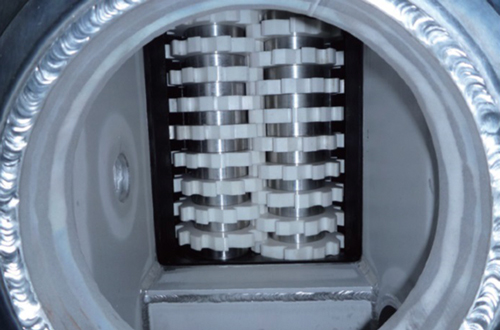

CERAMICS CUTTER is an abrasion- and corrosion-resistant cutter designed exclusively for the inline SUMICUTTER model, taking the place of conventional metal cutters.

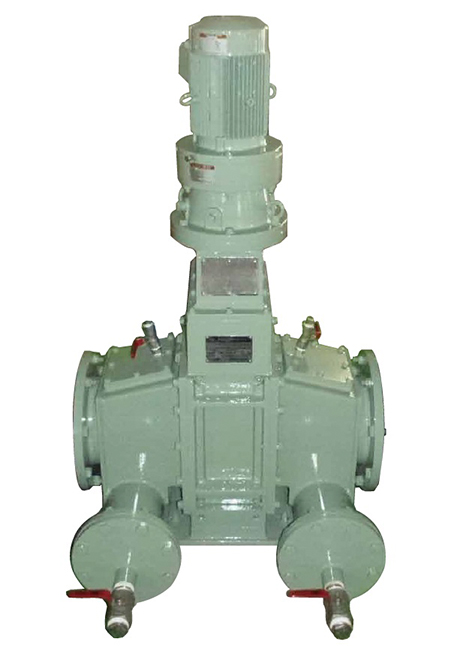

External view

SUMICUTTER interior

CERAMICS CUTTER

The SUMICUTTER safeguards against various equipment problems, including damage to and clogging of pumps and dehydrators. The product reduces the labor required to respond to equipment problems and related expenses.

Offering a unique waterproof design, the SUMICUTTER crushes solids in water, eliminating the need for lifting and disposing of solids and solving odor and sanitation issues.

The cutter boasts powerful crushing and grinding performance. It processes wood chips and empty cans with ease and leaves no stagnant solids in front of the crusher.

Typical solids crushed by the SUMICUTTER

The SUMICUTTER incorporates an innovative and proprietary self-cleaning function that keeps the cutting section clean at all times, eliminating the need for daily maintenance.

Maintenance requirements are minimal, since enclosed permanent grease lubrication systems are used to lubricate all parts. The simple structure allows easy disassembly—for example, if necessary to replace the cutter.

An arc-shaped horizontal screen enables processing of large volumes of sewage, while a scraping rake prevents screen clogging to ensure the equipment operates in a clean and stable state.

Waterway installation type: Deployed in waterway of grit chamber at treatment facility or relay pump station

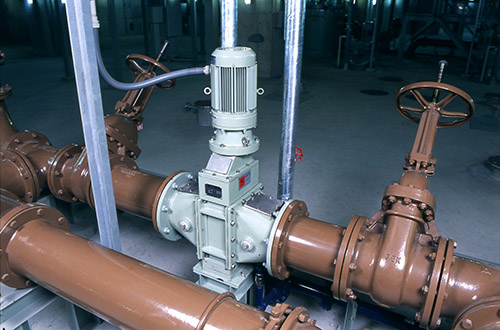

In-line type: Deployed in inlet/outlet pipe of sludge condensation equipment or sludge digestion tank facility

Horizontal-type: Deployed in the latter stage of automatic particle-screening equipment or in sludge incineration equipment

The following options are available: