Reducing operating costs

Proposals for reducing operating costs—Electricity & Sludge Disposal costs

Proposals for reducing operating costs—Electricity & Sludge Disposal costs

Facilities to generate methane gas from Waste/Waste Water

Unique ideas to minimize foot print of the WWT system

For aging facilities built decades ago, We proposes not just ways to extend equipment service life but ideas for improving performance and functionalities.

We offer equipment and systems that are easy to operate and manage; save space; ensure consistent, reliable processed-water quality; and provide high processing capacity performance.

Our special systems for wastewater and waste fluids that can’t be processed by conventional industrial WWT systems.

Our BIOIMPACT anaerobic treatment system provides various benefits, such as energy recovery, reduced electricity consumption, less generated sludge, and smaller footprints. The system is backed by a substantial track record of successful operation, and its applications are expanding to the chemical and pulp fields.

From its extensive system line up, We proposes the ideal system for specific raw water conditions, discharge conditions, and equipment operating procedures.

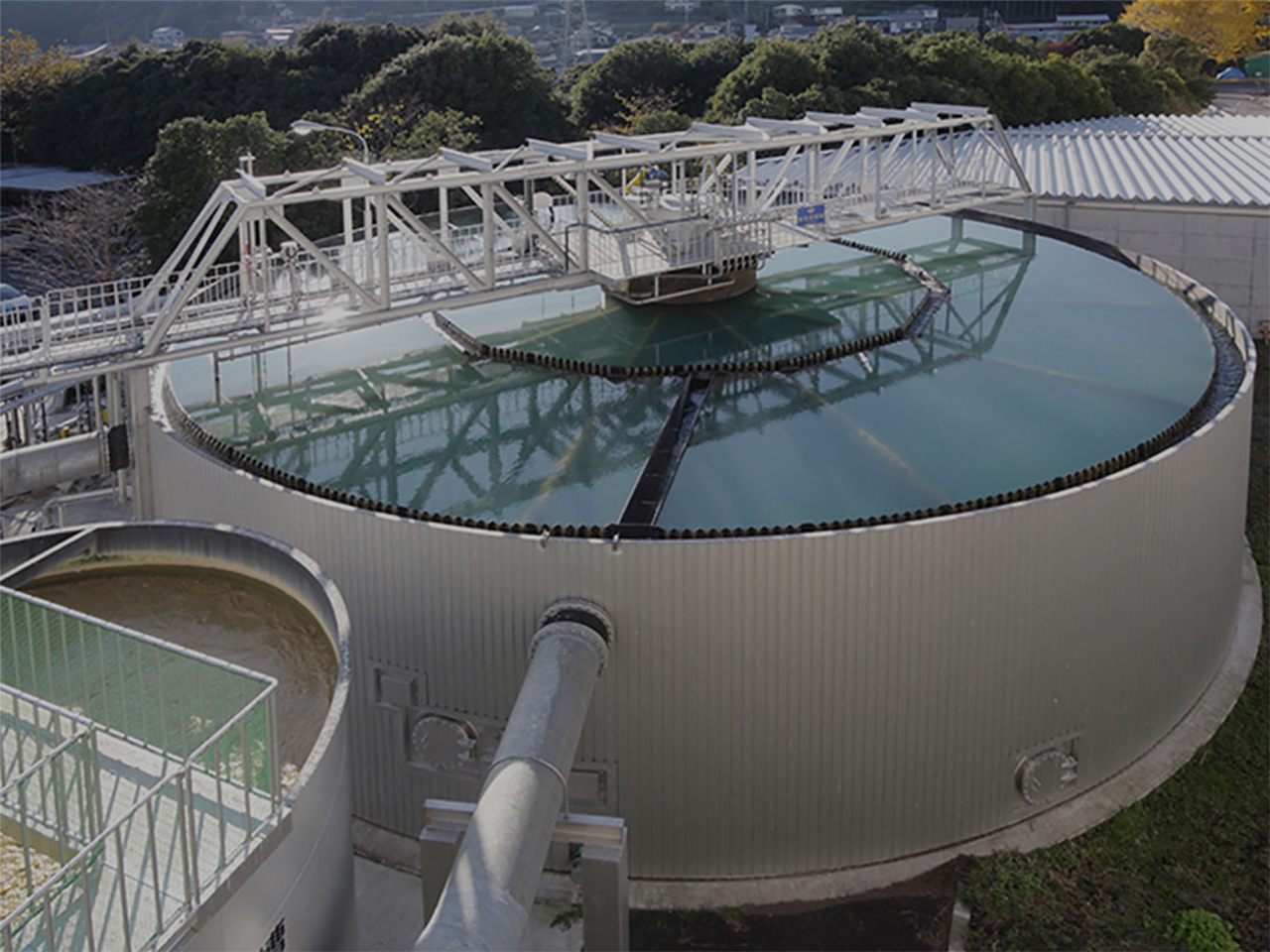

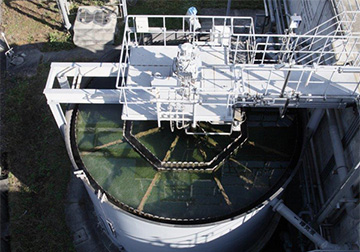

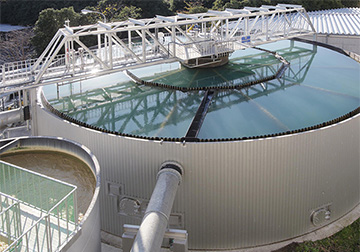

SUMITOMO’s SUMI-THICKENER super high-loading coagulation system offers numerous benefits, such as space saving and reliability. SUMI-THICKENER is installed in more than 250 facilities in various industries.

We deliver water/pure water treatment and recovery systems to companies that operate primarily in the food, chemical, pulp & paper, and steel industries.